|

|

|

KRM

Ares 2713 Soladrill

Quality

sowing means better germination and more even emergence. Utilizing a robust plastic hopper further reduces the weight of the Ares 2713 allowing smaller lower horsepower tractors to be used for significant

crop establishment cost savings.

|

|

|

|

KRM

Elite Coulter

|

|

Elite

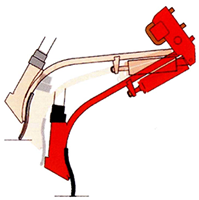

tine coulters are mounted in three rows (4 on solo drills) on equal length arms.

Pressure is supplied by a heavy duty spring positioned at

a shallow angle below the tine. This geometry ensures that

for each movement of the tip the corresponding deflection

of the spring is small resulting in more even pressure and

therefore depth. This system works equally well when shallow

drilling (rape) or deep drilling (peas) as well as in varying

soil conditions.

|

|

|

Arranged

over 3 evenly spaced rows, the Elite tine

coulters are able to handle large amounts of surface trash without

blockage. Solo drills feature an additional row of coulters for greater clearance.

|

|

| |

KRM PT Coulter |

|

PT tine coulters are mounted in four rows on equal length arms.

The top mounted coil spring delivers 60kg of pressure at the tip for improved penetration in min-till seedbeds or when drilling direct. The narrow (12mm) tip ensures minimal disturbance for improved weed control. The easy to replace tip has single bolt fixing and a tungsten carbide tip ensuring long life performance. |

|

Solo drills with PT coulters as shown opposite feature 4 rows of coulters for maximum inter row clearance this allows the drill to handle large amounts of trash without blockage. Drills fitted with a cultivator have 3 rows of coulters to minimise the overall length of the drill. |

|

| |

|

Standard

Features

|

|

|

The solatronic

control box monitors all key areas of sowing including; forward

speed, area sown, fan speed, hopper level and tramline management.

Further details

of this and other electronic solutions for variable rate drilling

can be found here

|

| When

on a tramline bout the tramline valves save seed back to the tank,

preventing over sowing and ensuring a clean start to each tramline.

As standard two shutoffs are used per wheeling, three can be specified

to accommodate large/flotation tyres. |

|

|

|

Heavy

duty, shear bolt protected markers leave an easily visible mark. The

angle of the large diameter marker disc's can be adjusted to ensure

a clear mark is left in difficult seed beds. The tramlining sequence

is advanced automatically when the operator moves the markers. |

|

|

The

position of the metering unit makes calibration and rate

setting simple. Rather than being tucked under the center

of the hopper the metering unit is located at the front

left hand corner greatly improving access.

The

central metering unit offers precise control of sowing rate

from 2 to 400kg/ha and ensures even seed spacing. The seed

is metered into a high speed air stream then distributed

to the individual coulters. This unit offers easy calibration,

simple setting and fast hopper emptying.

|

|

|

|

|

Drive for

the metering unit is supplied by a shaft from one of the drills

large flotation wheels ensuring constant drive. Accurate calibration

is performed simply by turning the wheel and collecting the

metered seed. To prevent the wheel running on when the drill

is lifted at the headland a brake wheel is fitted. |

|

|

.

|

The

sowing depth is set centrally using two ratchet adjusters. The

parallel linkage design ensures equal depth across the four

row of coulters. Wing support wheels are standard across the

range. Mounted at the extremity of the wing these wheels allow

the frame to follow ground contours. To ensure accurate depth

setting the wing support wheels are fitted with an identical

depth scale to those on the central depth adjusters. |

|

|

| |

|

|

Two

rows of staggered following harrow tines leave a level seedbed. The

maximum working depth of the tines can be adjusted as can tine pressure

and angle. |

| |

|

|

Ares Solo

As a solo drill

the Ares is available in 4, 4.5, 4.8, 5, and 6m widths. Even in

wider widths the compact design of this drill allows a low horsepower,

lightweight tractor to be used. Resulting in reduced fuel usage

and compaction whilst maintaining high daily work rates. Standard

specification includes hydraulic drive fan.

|

| |

|

|

Ares Integrated

Cultivator

Here the cultivator

is integrated into the drill design allowing the weight of the hopper

contents to remain close to the tractor for reduced lift requirement.

It features two rows of adjustable tines to provide

initial loosening prior to sowing. Suitable for use in a wide range

of conditions including heavy, wet soils and Min-Till incorporated

seed beds.

|

| |